These ladders are permanently affixed to a structure, often used for routine access to equipment or rooftops.

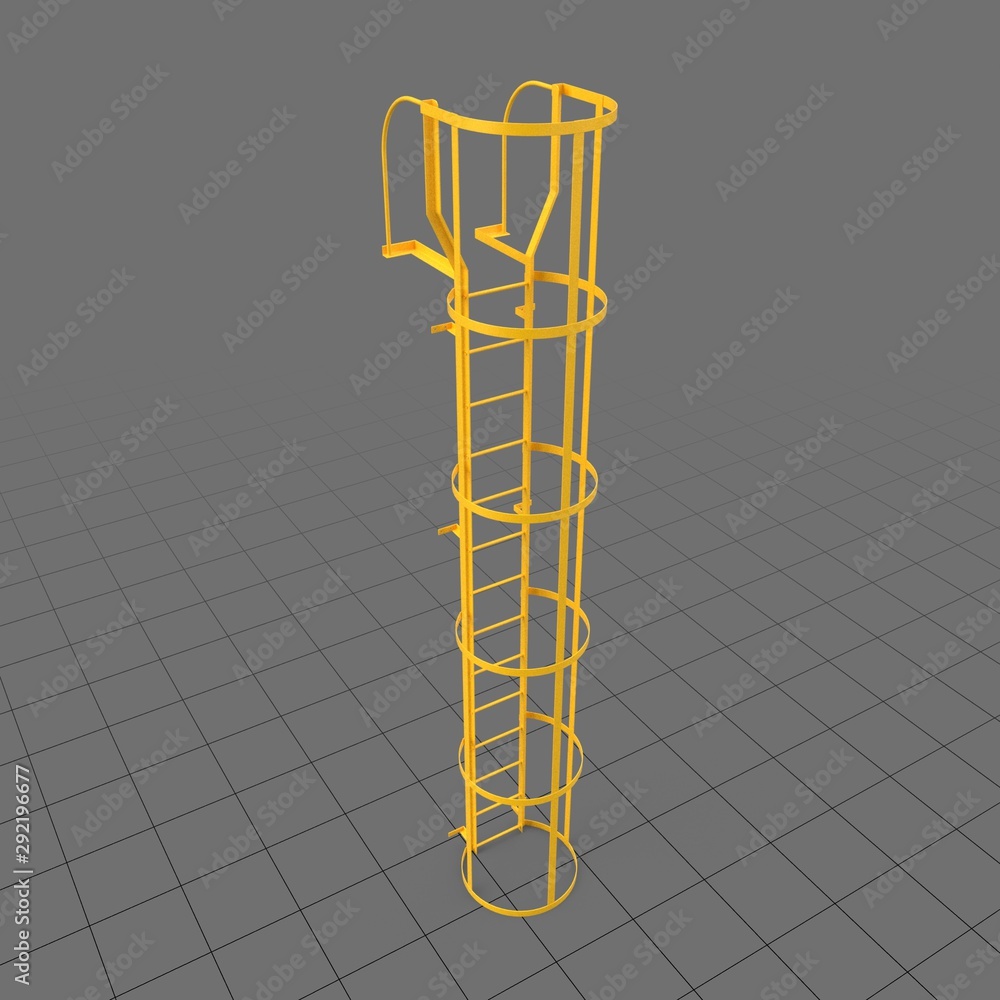

Industrial cage ladders, also known as safety or caged ladders, are designed to be safe and secure for climbing high elevations, often used in industrial settings. These ladders have a cage protecting the climber, primarily intended to enable the worker to lean back against the cage for safety and rest as needed.

What are the primary uses?

- Access to Elevated Levels: The most common use of cage ladders is to provide safe access to elevated levels, such as roofs, machinery, platforms, tanks, or upper floors of an industrial facility, where using a regular ladder may not provide enough safety.

- Maintenance and Inspection: Cage ladders are frequently used to provide access to machinery or systems that need regular maintenance or inspection. They are common in facilities with elevated machinery such as manufacturing plants, chemical plants, or power stations.

- Access to Utility Structures: Cage ladders are often used in the utilities sectors, such as water, electricity, and telecommunications, to allow workers to safely access utility structures like water towers, electrical pylons, or communication towers.

- Roof Access: They are also used for safe roof access, particularly in buildings where regular roof maintenance, inspections, or servicing of rooftop equipment is required.

- Emergency Exits: In some cases, cage ladders may serve as emergency exits, particularly from elevated platforms or work areas, providing a safer descent option than a regular ladder.

- Access to Storage Areas: Cage ladders are often found in warehouses or storage facilities, allowing safe access to high shelving or storage areas.

- Marine and Offshore Access: Cage ladders are used in marine and offshore applications, such as on oil rigs or ships, to allow safe vertical access in environments where conditions can be slippery or unstable.

Safety regulations, such as those set out by OSHA, must be followed when using cage ladders, including proper use of personal fall protection equipment and adherence to safety practices when climbing.

OSHA (Occupational Safety and Health Administration) sets forth regulations for the design, installation, and use of caged ladders in industrial settings. These guidelines are designed to ensure the safety of employees. Key points for an OSHA-compliant caged ladder include:

Compliance:

- Cage Design: Cages must extend a minimum of 42 inches above the top of the landing, unless other acceptable protection is provided. The cage must also extend down the ladder to a point not less than 7 feet nor more than 8 feet above the base of the ladder.

- Cage Size: The cage should not extend less than 27 inches, or more than 30 inches from the centerline of the step or rung, and should not be less than 27 inches in width.

- Ladder Safety Devices: All ladders that are more than 24 feet in height must have a personal fall arrest system or a ladder safety system.

- Spacing: The steps or rungs of the ladder must be evenly spaced, not less than 10 inches apart and not more than 14 inches apart, measured from the centerline of the rungs or cleats.

- Landing Platforms: If the total length of a climb equals or exceeds 24 feet, landing platforms must be provided at maximum intervals of 150 feet.

- Materials and Conditions: The materials used should be capable of withstanding the conditions of the environment where the ladder is used. Also, the ladder must be free of sharp edges, burrs, or other safety hazards.

- Clearance: There must be a minimum clearance of 7 inches from the ladder to any obstruction behind it. On the climbing side, the minimum perpendicular clearance to the nearest permanent object is typically 30 inches.

- Inspections: Regular inspections of caged ladders must be conducted to ensure safety and maintenance.

Remember, these are general guidelines and the specific requirements may vary. Always refer to the most recent OSHA regulations to ensure full compliance.